A sudden drop in pressure. The hiss of escaping steam. A puddle forming where the floor should be dry. In an industrial facility, these aren’t just minor inconveniences; they are the warning signs of a potentially catastrophic failure. When a leak occurs in a high-pressure system, time immediately becomes your most valuable resource. Every minute of delay can escalate safety risks, environmental hazards, and financial losses due to unscheduled downtime.

For plant managers and maintenance engineers, the ability to respond instantly to these critical situations is the difference between a minor maintenance event and a major operational shutdown. Rapid response leak sealing allows facilities to address containment breaches without taking assets offline, maintaining productivity while ensuring the safety of personnel.

This article explores the critical nature of emergency leak sealing, the methodologies used to contain high-pressure leaks online, and how partnering with experts like SEALTEC can safeguard your infrastructure.

Key Takeaways

- Safety First: Immediate leak sealing mitigates fire hazards, toxic exposure, and structural damage, protecting your workforce and the environment.

- Avoid Shutdowns: Online leak sealing technologies allow repairs to be made while the system remains under full pressure and temperature, preventing costly production halts.

- Proactive Strategy: Combining emergency repairs with long-term industrial piping solutions ensures asset integrity and extends the lifespan of your equipment.

The True Cost of an Unresolved Leak

It is easy to underestimate a small drip, especially in a massive facility with miles of piping. However, under high pressure or temperature, a minor leak can erode the sealing surface rapidly, turning a manageable issue into a blowout.

The impact of a leak extends far beyond the immediate repair costs.

- Operational Downtime: If a line must be shut down to fix a flange or valve, production stops. For refineries or power plants, this downtime can cost hundreds of thousands of dollars per hour.

- Environmental Compliance: Leaking chemicals or hydrocarbons can lead to severe regulatory fines and remediation costs, not to mention damage to the company’s reputation.

- Personnel Safety: High-pressure steam cuts like a knife, and toxic chemical releases can be lethal. Containing the leak immediately is a fundamental safety requirement.

Understanding Industrial Leak Sealing

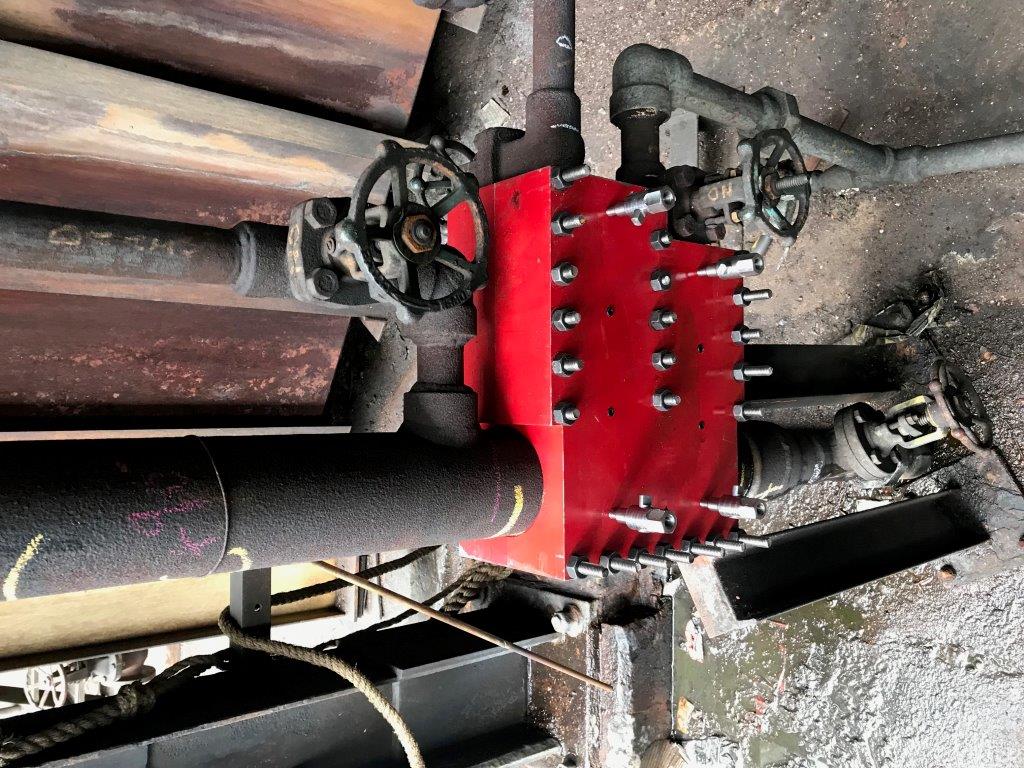

Industrial leak sealing is a specialized engineering discipline designed to restore the integrity of a pressurized system without isolating it or shutting it down. This process, often referred to as “online leak sealing,” involves designing and installing a custom enclosure or fixture around the leaking component.

Once the hardware is installed, a specialized sealant compound is injected into the void between the enclosure and the leaking component. This compound creates a new seal, effectively stopping the leak. The sealants are engineered to withstand extreme temperatures, pressures, and chemical environments, ensuring they do not degrade once inside the system.

This method is applicable to a wide range of components, including:

- Flanges

- Valves (packing and bonnets)

- Piping elbows and tees

- Expansion joints

- Heat exchanger joints

By utilizing this approach, facilities can keep running at full capacity until a scheduled turnaround or maintenance window allows for a permanent replacement.

Common Culprits Behind Critical Leaks

To effectively manage leaks, you must understand where they come from. While every system is unique, the stressors placed on industrial infrastructure often lead to predictable failure points.

Thermal Cycling

Piping systems expand and contract as temperatures fluctuate. Over time, this movement can loosen bolts on flanges or degrade gaskets, creating a pathway for the medium to escape.

Vibration

Rotating equipment like pumps and compressors transmit vibrations through the piping network. Constant vibration can cause fatigue in the metal or loosen mechanical joints, leading to seal failure.

Corrosion and Erosion

Chemical attack (corrosion) or the physical wearing away of material by fluid flow (erosion) can thin pipe walls and damage sealing surfaces. This is particularly common in elbows and reducers where flow turbulence is high.

Improper Installation

Human error during assembly—such as uneven bolt torque or improper gasket seating—remains a leading cause of premature joint failure.

Comprehensive Industrial Piping Solutions

While emergency response is vital, it functions best as part of a broader strategy. Reactive maintenance fixes the immediate problem, but proactive asset management prevents the problem from recurring.

Leading service providers like SEALTEC do not just plug holes; they offer holistic industrial piping solutions. This involves analyzing why the leak occurred and implementing measures to strengthen the system against future failures. This might include:

- Pipe wrapping: Using composite materials to reinforce thinned or damaged pipe walls.

- Hot tapping: Creating new branch connections while the line is in service to bypass damaged sections.

- Line stopping: Temporarily plugging a line to isolate a section for repair without draining the entire system.

Moving from a purely reactive stance to a reliability-centered maintenance approach helps facilities predict failures before they become emergencies.

The Sealant Injection Process

When you call for emergency assistance, the team arrives with a clear protocol. The safety of the technicians and the integrity of your plant depend on following a strict procedure.

- Assessment: Technicians inspect the leak to determine the pressure, temperature, and medium involved. They measure the gap and condition of the leaking component.

- Design and Fabrication: If a standard clamp isn’t suitable, engineers design a custom clamp or enclosure. This hardware is fabricated to ASME code specifications to ensure it can contain the system pressure.

- Installation: The enclosure is fitted over the leak. This step often requires precision handling, as the leak is still active during installation.

- Injection: A sealant injection gun is attached to ports on the enclosure. The sealant is pumped in slowly. As it fills the cavity, it cures and hardens, cutting off the leak path.

- Verification: The repair is tested to ensure zero emissions and structural stability.

Securing Your Facility’s Future

Leaks are an inevitable reality of operating complex industrial plants, but they do not have to result in disaster. The technology exists to handle these crises safely and efficiently, keeping your product flowing and your workers safe.

By prioritizing rapid response and partnering with specialists in industrial leak sealing, you transform a potential crisis into a manageable maintenance task. Don’t wait for the alarm to sound to decide on your response plan. Evaluate your critical assets now and ensure you have a partner like SEALTEC ready to deploy when seconds count.