ON LINE PIPING SOLUTIONS for INDUSTRIAL FACILITIES

Keeping Your Operations Running: Specialized Services for Industrial Facilities

In the demanding environment of an industrial facility, every minute of uptime counts. Unplanned shutdowns, system modifications, and routine maintenance can create significant operational challenges. Sealtec delivers specialized, on-stream solutions designed to maintain system integrity, enhance safety, and maximize efficiency without disrupting your production schedule. We understand the critical nature of your operations and provide reliable, swift, and precise services to keep your plant running at peak performance. Our experienced technicians are equipped to handle complex challenges, ensuring your facility remains productive and safe.

Our Core Industrial Services

Hospitals require specialized approaches to meet their unique challenges. Sealtec USA offers a comprehensive suite of services tailored to address the operational, safety, and compliance needs of healthcare environments:

Stop leaks without a shutdown. Our on-line leak sealing service addresses leaks of steam, water, hydrocarbons, and various chemicals under live process conditions. By injecting proprietary compounds into a custom-engineered enclosure, we create a durable, long-lasting seal, saving you the immense cost and logistical hassle of an unscheduled outage.

Need to add a new branch connection to a live system? Our hot and wet tap services allow you to safely tie into existing piping or vessels without shutting down or draining the system. We provide a new, flanged connection point on pipelines containing everything from water and gas to chemicals and steam, ensuring your expansion or modification projects proceed on schedule.

Isolate a section of pipe for maintenance or repair without draining the entire system. Pipe freezing creates a solid, temporary ice plug using liquid nitrogen, providing a reliable and safe isolation barrier. This method is ideal for valve replacements, equipment tie-ins, and pipe repairs, saving significant time and resources associated with system drainage and refill.

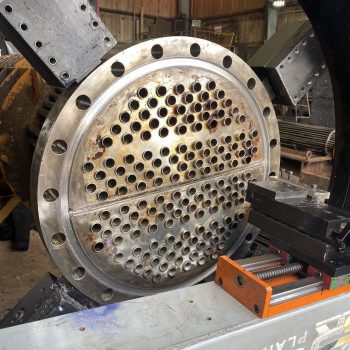

Bring the machine shop directly to your job site. Our portable field machining services deliver precision cutting, beveling, flange facing, and milling for a wide range of applications. This on-site capability eliminates the need to transport large components, reducing downtime and ensuring a perfect fit and finish for repairs, modifications, and new installations.

For reliable, temporary line isolation in low-pressure systems, our bagstop service offers a safe and effective solution. Inflatable bags are inserted into the line to stop flow, allowing for maintenance, repairs, or tie-ins. This technique is particularly useful in gas distribution lines and other systems where a complete shutdown is impractical.

Protect and reinforce your critical piping infrastructure with our composite pipe wrapping solutions. This service restores strength to corroded or damaged pipelines, providing a durable, long-term repair that conforms to industry standards. The wrap reinforces the pipe’s structural integrity, extending its service life and preventing future failures without requiring pipe replacement.

Why Choose Sealtec USA for Industrial Facilities

When it comes to maintaining and protecting your industrial facility, you need a partner you can trust. SEALTEC USA’s reputation is built on decades of experience, technical excellence, and a commitment to delivering tailored solutions that keep operations running safely and efficiently. Our team is composed of highly trained experts who prioritize safety and maintain strict adherence to industry standards. We use innovative technologies and proven methodologies to resolve both routine and complex challenges without unnecessary downtime.

Our track record of reliability, responsive service, and successful project outcomes makes SEALTEC USA the preferred choice for industrial facilities across the country. Trust us to safeguard your operations and deliver enduring solutions that stand the test of time.