ON LINE PIPING SOLUTIONS for POWER PLANTS

Keeping Power Flowing: Specialized Services for Power Plants

Power generation facilities operate under immense pressure and demand the highest standards of safety and operational uptime. An unexpected shutdown or leak can lead to significant downtime, lost revenue, and potential safety hazards. SEALTEC USA provides a comprehensive suite of specialized technical services designed to keep your power plant running safely and efficiently, minimizing disruptions and maximizing productivity.

Our expert technicians are available 24/7/365 to deliver rapid, reliable solutions that address critical infrastructure challenges without requiring a full system shutdown. We understand the unique demands of the power industry and are committed to maintaining the integrity of your operations.

Our Power Plant Services

We offer a range of specialized services to address maintenance and repair needs swiftly and effectively, ensuring your facility remains online and operational.

Leaks in steam, water, or chemical lines can compromise safety and efficiency. Our on-line leak sealing services allow us to repair leaks while your systems remain active and under pressure. This eliminates the need for costly shutdowns, saving you time and money. We can seal leaks in various components, including flanges, valves, pipes, and other critical fittings.

Need to add a new connection to an existing pipeline without interrupting service? Our hot and wet tapping services enable us to create a new branch connection on pipelines that are in service and under pressure. This process is essential for system expansions, modifications, or installing new instrumentation without disrupting your plant’s output.

When a section of pipe needs isolation for maintenance or valve replacement, our pipe freezing services provide a safe and effective solution. By creating a solid ice plug within the pipe, we can isolate specific sections without draining the entire system. This method is fast, non-intrusive, and ideal for situations where no system shutdown is planned.

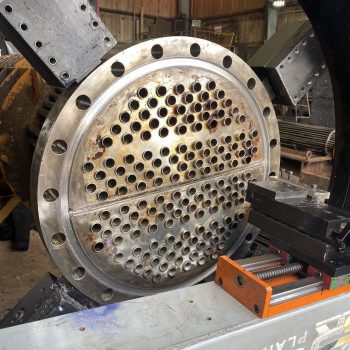

Our portable field machining equipment brings the workshop directly to your site. We provide precise, on-site machining services for tasks such as flange facing, pipe cutting and beveling, and base milling. This capability ensures that components meet exact specifications, guaranteeing a perfect fit and seal, all performed at your facility to reduce downtime.

For low-pressure gas or fluid lines, our bagstop services offer a reliable method for temporary line isolation. This technique involves inserting inflatable bags to create a secure blockage, allowing for safe repairs, modifications, or tie-ins on live lines. It’s a proven solution for maintaining and upgrading distribution systems without a complete shutdown.

Protect your pipelines from corrosion, abrasion, and environmental damage with our composite pipe wrapping solutions. This advanced repair method reinforces and restores the structural integrity of weakened or damaged pipes. It’s a durable, long-term solution that extends the life of your critical assets and prevents future leaks or failures.

Why Choose Sealtec USA for Power Plants

When operational reliability is non-negotiable, you need a partner with the experience and expertise to deliver. SEALTEC USA is the trusted choice for power plants across the country.

- Unmatched Expertise: Our technicians possess deep knowledge of power plant systems and the complex challenges they present. We have a proven track record of successfully completing projects in the most demanding environments.

- Commitment to Safety: Safety is at the core of everything we do. We adhere to the strictest safety protocols and industry standards to ensure the well-being of your personnel and the integrity of your facility on every job.

- Innovative, Cost-Effective Solutions: We specialize in solutions that avoid shutdowns. Our on-line services are designed to keep your plant generating power while we perform critical repairs and maintenance, saving you significant operational costs.